The term “The Internet of Things” was coined by Kevin Ashton in a Procter & Gamble presentation in 1999, and since then it has caught on as a general description for connecting machines and even everyday objects to the internet.

Most commonly in the business context, the Internet of Things (IoT) is all about collecting data.

It’s about putting this data to use to make businesses more profitable and safe.

What types of data do businesses collect?

Data about the vibration of pumps, so that you know when to replace them. Or the pressure in pipes, so they can be monitored for when they will split. Or the quality of air, so that the danger to workers can be monitored. The list of data collection applications is endless.

But what does the Internet of Things mean for the OSHA obligations of large businesses?

Let’s leave aside for the moment the implication of what it means for a business to “know everything”, and firstly just look at the IoT trend itself.

Is this IoT trend catching on?

Yes. Yes it is.

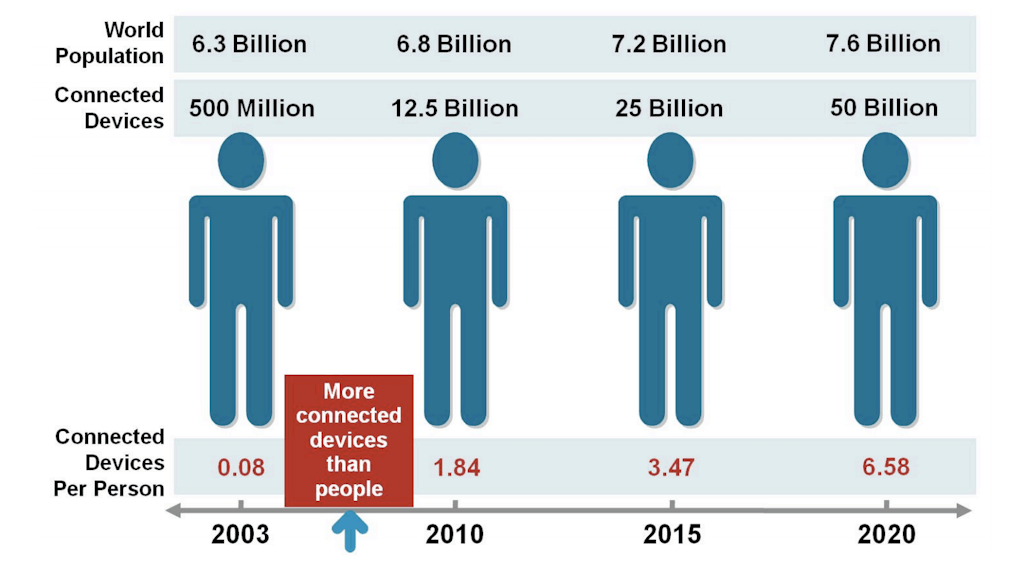

There is an exponential growth in the number of connected devices, and this trend according to Cisco, will see connected devices at 50 billion by 2020.

Note above that this trend is well established now, but it is also coming from a low base.

This means that although an astounding amount of machines and objects are already connected to the internet, that experts agree that we are still in the very early stages of the IoT trend.

There is much more room for this trend to continue.

Many large businesses have woken up too, and they now have explicit IoT programs in place to capitalize on this new technological trend.

What this means in practice is that businesses, and in our experience especially very large businesses, have a lot more safety data on hand nowadays…

What does the IoT mean for safety?

All this extra data creates a new OSHA problem for large businesses and their HSE professionals.

Why? Because the legal implications for a business that “knows” something is going to go wrong, but then doesn’t act, can be very significant indeed.

For example: If a business is measuring the fact that an oil well is experiencing a pressure spike and may well explode, it’s imperative that workers nearby have this knowledge too, so they can avoid the explosion.

How exactly does a business do this?

How do you move all this new HSE data into the hands of workers, so that they can keep themselves informed and safe?

Let’s look at a practical example of one IoT dataset, and how a business may tackle the challenge of pushing the right HSE data into the hands of the right workers.

Example – Lightning strike risk:

It was once the case that lightning strike risk was very difficult to share with those workers at risk, but because of the IoT that is no longer the case:

As with the lightning warnings above, the same safety techniques can also be used for other IoT data types.

That’s what SaferMe is built for. SaferMe is set up to make sure workers have the real-time safety information they need to, no matter where they are. This includes safety data from within each business, but also external to the business, so that workers can take safe and real-time corrective actions.

You can get a free demo of the SaferMe platform here.

Subscribe below to get future posts from SaferMe

We send out emails once a month. We won't share your email with anyone.